SorbiTech™ CMS 350KT Rapid Adsorption Carbon Molecular Sieve for High Purity

High Efficiency CMS 350KT for Industrial Nitrogen Generation

CMS 350KT is engineered for large scale nitrogen generation systems, offering rapid adsorption rates and excellent energy efficiency. With nitrogen purity levels reaching up to 99.99 %, CMS 350KT is the preferred choice for critical industrial applications including oil and gas, chemical processing, and the food industry. Its robust pellet shape and high crush strength ensure low dust formation and reliable long term performance, delivering optimal productivity and consistent nitrogen purity.

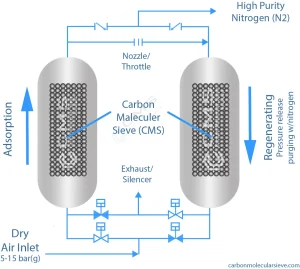

How CMS 350KT Works

CMS 350KT uses a high surface area carbonaceous adsorbent with precisely controlled pores narrower than 10 Ångstroms, which enables efficient selective adsorption of oxygen during the Pressure Swing Adsorption (PSA) process.

The Carbon Molecular Sieve rapidly adsorbs oxygen molecules at elevated pressures and releases them during depressurization, allowing nitrogen to flow continuously at high purity.

This rapid pressurization depressurization cycle enhances overall energy efficiency in PSA plants.

Performance and Operating Conditions

CMS 350KT can achieve nitrogen purities up to 99.99% depending on system configuration and operating parameters. CMS 350KT operates effectively within temperature ranges of 5 °C to 50 °C, pressures and cycle times from 40 to 90 seconds. Advanced PSA cycle techniques such as equalization, backflow, purge, and cutting enhance nitrogen recovery and system efficiency.

Loading and Handling Best Practices

Proper loading of CMS 350KT into PSA adsorption vessels is essential to achieve high packing density, uniform flow distribution, and low pressure drop, all of which reduce gas channeling and dust formation. Depending on vessel shape and accessibility, loading techniques include:

- Direct loading

- Dense loading

- Snowstorm filling

Drums should be opened and filled in dry conditions promptly to preserve adsorbent activity. CFL mats, if present, should be replaced. After filling, the bed must be compacted and fixed appropriately. SorbiTech™ technical support team is available to provide customized guidance for specific vessel configurations.

Technical Specifications of Carbon Molecular Sieve (CMS)?

|

Specifications

|

details

|

|---|---|

|

Material Composition |

High Purity Carbon |

|

Nitrogen Purity |

Up to 99.99% |

|

Particle Size Options |

1.0mm – 2.2mm |

|

Bulk Density |

AS Demand |

|

Moisture Content |

≤ 1.0% (Low for high efficiency) |

|

Packaging Options |

70 Kg Drums (Approx. 100 L) 137 Kg Drums (Approx. 200 L) |

Why Choose Our Carbon Molecular Sieve (CMS) ?

We offer high performance Carbon Molecular Sieve engineered for superior adsorption.

CMS 350KT For PSA Nitrogen Generator

CMS 350KT combines enhanced adsorption capacity with robust mechanical strength, delivering stable nitrogen purity and extended bed life in medium duty PSA systems.

Type

Carbon Molecular SieveShape

Pellets

Requests

Download

Fast Delivery

Available In

Stock

Environmental

Friendly

Affordable

Price

Fast Delivery

Available In

Stock

Affordable

Price

Environmental

Friendly

What Makes Our Carbon Molecular Sieves (CMS) the Best Choice?

As part of the Sorbitech™ brand family, we provide CMS 350KT with guaranteed high quality and performance, backed by comprehensive technical support. Our products are stocked strategically for fast delivery worldwide, ensuring reliable supply across all major markets.

Optimize Your Industrial Nitrogen Generation Today

Whether you operate in oil and gas, chemical processing, or the food industry, CMS 350KT offers a dependable, energy efficient solution for your nitrogen needs. Contact Sorbitech to discuss your system requirements, receive expert guidance, and get a competitive quote tailored to your flow rate, purity targets, and vessel configuration.

Get in touch now and empower your nitrogen generation with Sorbitech’s CMS 350KT, Quality you can trust, delivered with unmatched service.