CMS Nitrogen Generation For Semiconductor Manufacturing

Semiconductor Manufactures using CMS Nitrogen Generation

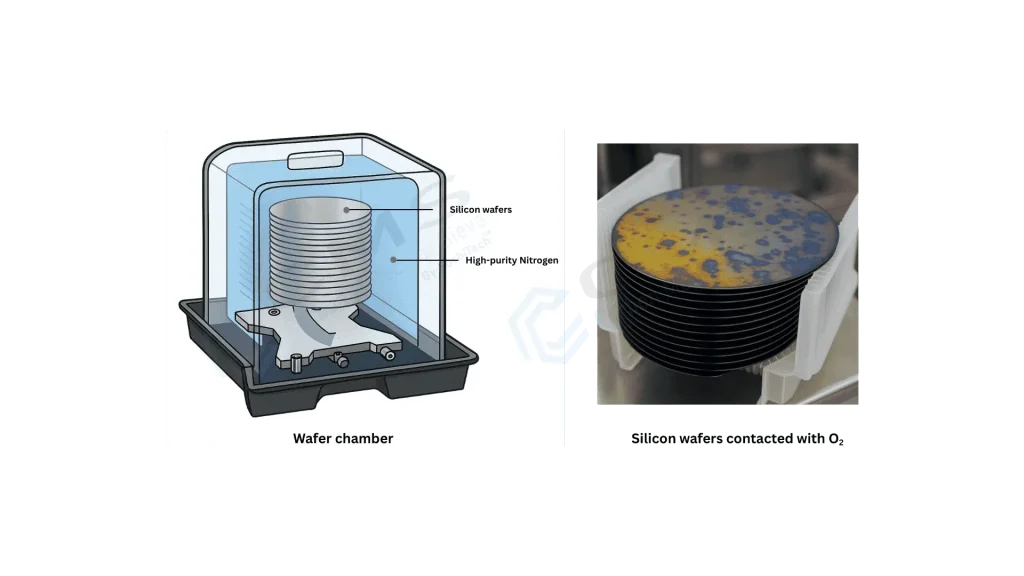

Semiconductor production demands extreme precision, as silicon wafers pass through many sensitive steps, including coating, plasma etching, ion implantation, furnace processing and packaging. Trace amounts of oxygen or reactive gases can impact microchip quality. It causes oxidation, dopant profile shifts, coating damage, and contaminants that may later cause electrical failures.

How is Nitrogen Used in Semiconductor Manufacturing?

- Photoresist coating and developing: CMS PSA nitrogen keeps humidity away from resist coating areas, thereby preventing swelling and maintaining precise dimensions.

- EUV & DUV Stepper Load Lock – Nitrogen flushes wafer loading chambers each cycle. Thus, keeps oxygen below 10 ppm and preventing photo acid pre-exposure.

- Dry etch and plasma asher: Nitrogen refills the chamber and removes fluorine residues, therefore avoiding sidewall oxidation that increases line edge roughness.

- Ion implantation process: Nitrogen from CMS PSA generators cools ion beam lines and stops ozone formation, consequently protecting wafers and corrosion of beam line components.

Benefits of Using CMS Nitrogen in a Semiconductor Manufacture

- Precise linewidth control: Keeping oxygen below 10 ppm during lithography prevents resist contamination, ensuring accurate dimensions and higher quality chips.

- Accurate Thermal Processing: Ultra-dry nitrogen prevents oxidation during rapid thermal processing, thus preserving chip structure reliability.

- Longer Copper & Aluminium Life: Nitrogen shields these metals in etch and plasma tools, thereby reducing corrosion and downtime.

- Continuous Tool Operation: On-site CMS units deliver nitrogen 24/7. Therefore, avoid interruptions from cylinder changes or gas deliveries.

Why Use Pure Nitrogen in Semiconductor Manufacturing?

- Stops Oxygen Damage: Prevents oxidation on copper and silicon, thereby keeping doping profiles stable and photoresists clean.

- Inert atmosphere: Nitrogen creates a safe, non-reactive environment in tools like load locks, etchers, furnaces, and ion implanters, preventing corrosion and reactions.

- Maintains Vacuum Quality: Purges chambers without introducing contaminants that could affect future processes.

- On-site generation: Converts compressed air into 99.999 % nitrogen, therefore eliminating delivery delays and ensuring uninterrupted operation.

Ensure Semiconductor Quality with Us

Contact us today to protect your semiconductor production from contamination, improve yields, and enhance operational efficiency using high-purity nitrogen generated onsite with SorbiTech™ Carbon Molecular Sieve (CMS).