Nitrogen Blanketing in Fuel Tank using CMS Nitrogen Generators

What is Nitrogen Blanketing in Fuel Tank Storage Using CMS Nitrogen Generation?

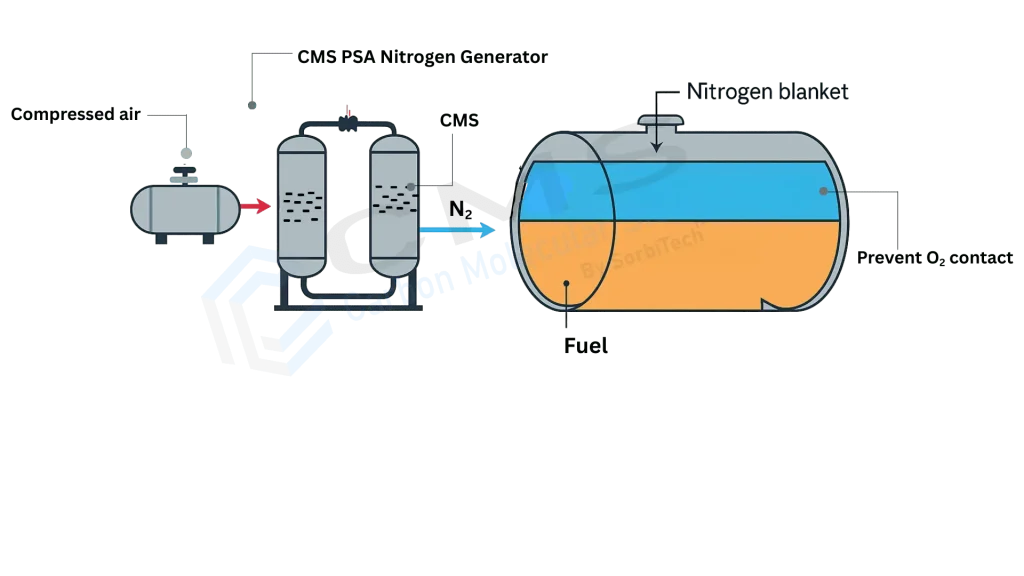

Nitrogen blanketing in fuel tank storage fills the empty space (headspace) above flammable liquid with clean, dry nitrogen from Carbon Molecular Sieve PSA generators. The nitrogen maintains slight positive pressure and lowers oxygen concentration. Thus, the atmosphere inside the tank stays safely below flammable limits, even if a spark occurs. Using CMS-generated nitrogen also blocks airborne contaminants from contacting the fuel. As a result, it helps maintain fuel quality, reduce corrosion, and enhance overall safety.

How CMS Work for Nitrogen Blanketing in Fuel Tank?

Nitrogen blanketing keeps the vapor space above diesel, gasoline, or jet fuel filled with dry, inert nitrogen from an on-site CMS PSA generator. It lowers oxygen to 8% or less, maintains slight positive pressure (15–50 mbar), and stops ignition while slowing oxidation and blocking moisture or pollutants.

- Generation: A CMS PSA unit separates nitrogen from compressed air, delivering 99.999% purity at ambient temperature and dew points below –60°C.

- Blanketing: The nitrogen flows to the tank nozzle and quickly fills the headspace, pushing oxygen out through a vent valve until the safe set point is reached.

- Pressure Control: A blanketing valve keeps the tank a few millibar above atmospheric pressure. When fuel is withdrawn or the liquid cools, the valve opens to admit fresh nitrogen; if pressure rises, a relief valve vents excess gas.

- Continuous Assurance: Analyzers verify purity, and the generator cycles automatically, so the blanket never falls below the critical oxygen threshold.

Key Benefits of Using CMS Nitrogen Generation for Fuel Tank Blanketing

- Eliminates ignition risk: Holding oxygen well below the fuel’s limiting oxygen concentration (below 8 %). A spark, static discharge, or hot work cannot trigger a fire or explosion inside the tank.

- Maintains constant tank pressure: Nitrogen automatically fills the tank space when liquid is pumped out or cools. It prevent vacuum conditions that could collapse floating roofs or suck ambient air back in.

- Simplifies regulatory compliance: Continuous logs of oxygen content and pressure from the CMS skid make it easy to meet standards. They also support fire safety audits.

- Cuts operating cost and emissions: On-site nitrogen generation removes the need for deliveries, thus reducing expenses and cutting emissions from transport and tank vents.

Why Choose High Purity Nitrogen from a CMS PSA Generator Instead of Other Inert Gases?

- Density: Nitrogen is heavy enough to sit calmly on the fuel but light enough to vent without over pressurising. CO₂ is too heavy; helium and argon are too light. CMS PSA skid makes purity to 99.999 % so blanket pressure stays balanced within the set point.

- No solubility or acidity concerns: Nitrogen is nearly insoluble in gasoline and does not form carbonic acid and corrosion.

- Lowest life cycle cost: Nitrogen produced onsite from CMS Pressure Swing Adsorption (PSA) systems significantly reduces costs compared to expensive gases like argon or helium. Avoids logistics complexity associated with cylinder or cryogenic deliveries.

- Simple feedstock and logistics: CMS nitrogen generators only require compressed air and electricity. Additionally, they offer simple operation, reliable 24/7 supply, low lifecycle costs, and easy maintenance, making them ideal for fuel tank blanketing.

Protect Your Fuel Storage with CMS Generated Nitrogen

Contact us to enhance fuel safety, maintain product purity, and prevent tank corrosion with high purity nitrogen generated onsite using SorbiTech™ Carbon Molecular Sieve (CMS).

Ready to simplify your nitrogen supply and ensure reliable, cost effective fuel tank blanketing?