What is Carbon Molecular Sieve?

What is Carbon Molecular Sieve (CMS)?

Carbon Molecular Sieve (CMS) is a specialized porous carbon material that separates gases based on molecular size and shape, with uniform pores about 0.3-0.5 nanometers wide. In the most common application, Pressure Swing Adsorption (PSA), Nitrogen Generation is used to produce high purity nitrogen. That traps smaller oxygen molecules while allowing larger nitrogen molecules to pass through. There are specialized grades, such as CMS 260L, CMS 350KT, CMS 420KT, and CMS 450HP, engineered to meet specific requirements for flow rates, purity targets, and operating conditions.

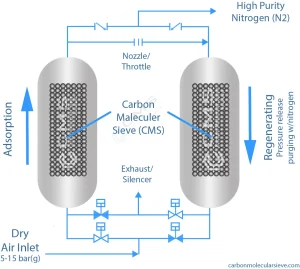

How Does CMS Work in a Nitrogen Generator?

- Adsorption: Compressed air enters a CMS packed vessel in a nitrogen generator.

- Molecular sieving: Tiny pores (~0.3–0.5 nm) in the carbon selectively capture oxygen and other small impurities.

- Nitrogen output: Clean, high-purity nitrogen exits the vessel.

- Regeneration: The system depressurizes the CMS bed to release captured gases and prepare it for the next cycle.

Carbon Molecular Sieve (CMS) Use Cases

Carbon Molecular Sieve is the go-to material for on site gas separation, especially nitrogen generation. Its tiny, uniform pores trap smaller molecules such as oxygen, carbon dioxide, and other particles, while allowing larger nitrogen molecules to pass through. This molecular “sieving” action delivers ultra high purity nitrogen (up to 99.999 %) with minimal energy input and a compact system footprint. On site nitrogen generators use CMS for metal heat treatment, food packaging, laser cutting, tire inflation, and more. And in air separation units for specialty gases in the semiconductor and pharmaceutical industries. read more>>

Key Features of Carbon Molecular Sieves

- Precise Pores: Uniform 0.3–0.5 nm pores selectively trap O₂, H₂O, and CO₂ while passing N₂.

- High Surface Area: 500–1,200 m²/g of internal area for maximum adsorption capacity.

- Fast Cycling: Adsorption/desorption in 30–120 seconds for continuous, on-demand gas.

- Stable & Durable: Withstands typical industrial temperatures and minor impurities for 5–7 years.

- Low Pressure Drop: Optimized pellet size minimizes airflow resistance and energy use.

- Strong & Robust: Crush strength ≥ 100 N/pellet keeps beds intact under pressure.

Production Process of CMS for PSA Nitrogen Generators

- Choose the precursor

Made from carbon rich materials such as coal, coconut shell, or thermoset polymers (e.g., phenolic resin, polyimide, PAN). The raw material selected determines the final pore structure and mechanical strength. - Shape the material

The precursor is mixed with a binder (often coal tar pitch) and then formed into pellets, beads, or monoliths via extrusion or granulation. - Stabilize / pre-oxidize

Polymers stabilize at ~150–320 °C in air to prevent melting and lock in the microstructure.

Coal based precursors may undergo mild oxidation to improve process stability. - Carbonize in an inert gas.

The shaped material is heated under an inert atmosphere to ~500–900 °C, and as a result, the process removes volatiles and creates a porous structure. - Activate

The carbon is partially “burned off” at 700-1000 °C using steam or CO₂. This step creates micropores and increases surface area. - Pore mouth narrowing

A hydrocarbon gas (e.g., benzene, toluene, propylene) is decomposed at ~650-800 °C, depositing a thin carbon layer at the pore entrances. This shrinks pore openings to ~0.3-0.5 nm, giving CMS its unique O₂/N₂ separation ability. - Quality control

Each batch is tested for surface area, density, crush strength, pore distribution, and moisture content.