How Can We Maintain and Load CMS in Nitrogen Generators

Proper loading and maintenance of Carbon Molecular Sieve (CMS) are critical for ensuring consistent nitrogen purity, extending the life of the adsorbent, and keeping a PSA nitrogen generator reliable over time. CMS works at the heart of the generator, separating oxygen from nitrogen, but it can only perform well if the bed is packed evenly, protected from moisture, and kept stable during operation. By preparing the vessel correctly, handling the media carefully, using the right filling method, and monitoring system performance, operators can maintain efficiency and avoid problems like channeling, dusting, or premature CMS failure.

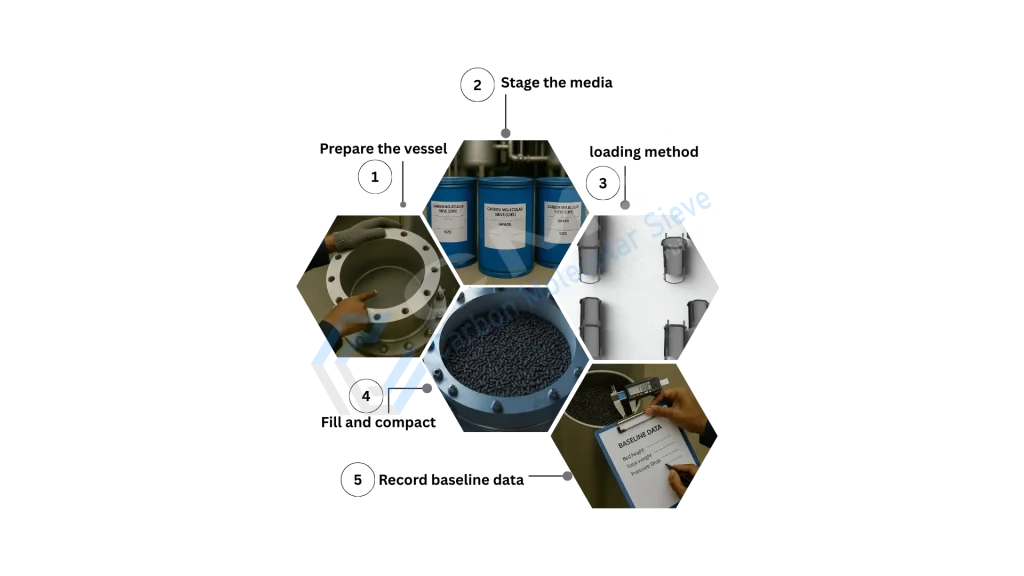

Prepare the vessel

Inspect screens and distributors for damage, and replace CFL mats or gaskets if required. Ensure the vessel interior is completely dry before filling.

Stage the media

Bring CMS drums to the installation area, confirm the correct grade and size, and check for any signs of damage. Keep the drums sealed until the moment of filling to prevent moisture absorption.

Select a suitable loading method

Choose between direct loading, dense loading, or snowstorm filling, depending on vessel design and accessibility. Aim for high packing density, even gas flow, and minimal channeling or dust formation.

Fill and compact

Load the CMS in dry conditions, keeping drop height low to limit pellet breakage. Tap or vibrate the vessel to settle the bed and install retainers to prevent media movement during operation.

Record baseline data

Measure and document bed height, total weight, and initial pressure-drop readings. This data will help in future performance comparisons.

What are the Initial startup after Loading?

- Make sure the compressed air feeding the system dew point is sufficiently low to protect the CMS.

- Start operation with conservative cycle times, then optimize based on performance. For high performance grades, adsorption cycles of 30-60 seconds are common.

- Measure and note the nitrogen purity and output rate to create a reference for future checks.

How do you maintain CMS in a nitrogen generator?

- Keep CMS dry by checking air dryers and filters often.

- Inspect pressure drop (ΔP) to detect early blockages or uneven flow.

- Keep vents, silencers, and pre-filters clean and replaced on schedule.

- Monitor nitrogen purity and output regularly to catch performance changes early.

When to Replace CMS

With clean, dry, oil free feed air and proper operation, Carbon Molecular Sieve (CMS) can last 3 years.

- Nitrogen purity or output stays low even after making operational adjustments.

- Pressure drop remains high despite cleaning and maintenance.

- The PSA needs longer cycles to maintain purity.

- Black dust or damaged pellets appear in downstream filters.

Want to know more about Carbon Molecular Sieve loading in nitrogen generators? Contact SorbiTech™. Our technical team will guide you with the right CMS solution for your operations, ensuring long lasting performance, stable nitrogen purity, and dependable quality.