How to Solve CMS Ash/Dust Emission in PSA Nitrogen Generators?

When a Carbon Molecular Sieve bed in a PSA nitrogen generator gives off constant ash or dust, it usually points to particle breakage or improper bed stability. long period of non use can also contribute to this issues. This problem reduces purity, clogs filters, and shortens the generator’s life.

- Control pressure and flow: Harsh valve switching or sudden pressure change can grind the CMS into dust. Always use smooth valve operation, proper equalization, and keep air velocities within design limits to avoid shock loads.

- Ensure clean, dry feed air: The inlet air must be clean and dry. Install and maintain coalescing filters, dryers, and oil vapor filters if using lubricated compressors. Oil or water contamination weakens the CMS and greatly increases dusting.

- Load the CMS properly: If the CMS bed is uneven, re-fill it using the Snowstorm Filling method. This will creates dense, uniform packing and reduces particle breakage compared to simple dumping.

- Check for physical damage: Damaged or weakened CMS pellets, or worn internal parts like screens and CFL pads, can lead to continuous ash formation. Inspect the bed during service and replace any damaged material or components.

Impact of Long Downtime

If a PSA nitrogen generator is left unused for a long period without proper preservation, the Carbon Molecular Sieve (CMS) can absorb ambient humidity or even oil vapors that seep into the vessel. This weakens the CMS pellets, making them brittle and prone to dusting when the system is restarted. In addition, the CMS bed may settle unevenly during inactivity, which increases the risk of channeling and particle breakage once pressure cycles resume.

CMS Preservation Guide for Long Downtime

- Purge the Towers with Dry Nitrogen: Flush the PSA vessels with clean, dry nitrogen before shutdown. This displaces humid ambient air and prevents the CMS from absorbing moisture.

- Seal the System Airtight: Close all valves and seal the towers to block outside air, dust, or oil vapors from entering during storage.

- Store in a Cool, Dry Environment: If possible, keep the generator in a location with low humidity and stable temperature to further protect the CMS.

- Restart Gradually: When putting the system back into service, pressurize and cycle it slowly. A soft restart reduces stress on the CMS bed and prevents sudden dusting.

Why Choosing the Right CMS Matters

While operating conditions and maintenance practices play a major role in preventing dust or ash emission, the quality of the Carbon Molecular Sieve itself is equally important. Inferior CMS materials are more brittle, generate excessive fines during operation, and lose performance faster.

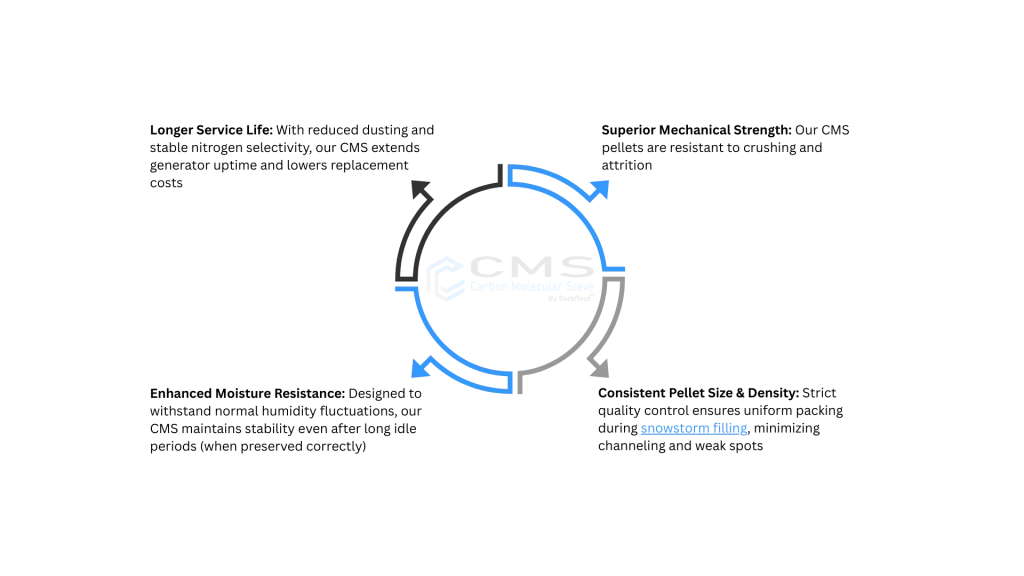

At SorbiTech™, we supply high strength Carbon Molecular Sieves that are engineered for: