Nitrogen Generation by Pressure Swing Adsorption (PSA)

Pressure Swing Adsorption (PSA) nitrogen generation is a widely used technology to produce high purity nitrogen gas (N₂) directly from compressed air. It relies on special adsorbent materials mainly Carbon Molecular Sieve to separate oxygen from nitrogen. Carbon molecular sieves traps oxygen and nitrogen flow through because of the porous structure. It’s a cyclic process that involves switching between high and low pressure to preferentially adsorb and desorb gases.

How to Implement PSA Nitrogen Generator?

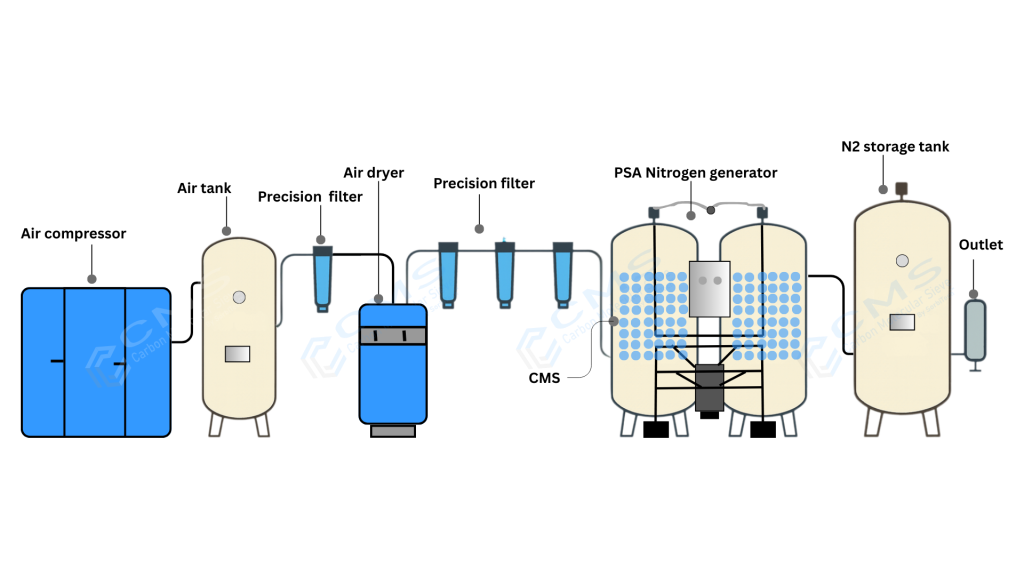

Designing a reliable PSA nitrogen system start by determining your required nitrogen flow rate and purity, then calculate the necessary air compressor and adsorption vessels based on these specifications and the Carbon Molecular Sieve (CMS) performance. The process involves filtering and drying compressed air, which then enters two CMS packed vessels in alternating cycles of adsorption (oxygen sticks to CMS, nitrogen passes through) and regeneration (oxygen desorbs as pressure drops, CMS purge with nitrogen) to produce continuous, high purity nitrogen. Here is the steps of implementing nitrogen generators:

- Determine Requirements

Define nitrogen purity (95%-99.999%), flow rate (Nm³/h), and delivery pressure (5-10 barg). Also set dew point targets (≤ -40 °C or ≤ -60 °C) and consider site conditions and operating hours. - Air Compression & Conditioning (protects CMS)

Use a compressor sized for 7–10 barg. Always pretreat air with filters and a dryer to keep it ultra-dry and oil-free, protecting the CMS and purity. - CMS Selection and Vessel Design

choose the right CMS grade based on the purity and flow requirements. Two adsorption vessels designed with the correct height-to-diameter ratio to minimize pressure drop and ensure efficient performance. CMS grades such as CMS 260L, CMS 350KT, CMS 420KT, and CMS 450HP meet the specific needs in terms of different flow rates, purity targets, and operating conditions. - PSA Cycle Design

PSA enables continuous nitrogen generation by cycling between two towers. In adsorption, CMS traps oxygen while nitrogen passes through. Pressure equalization balances energy, and regeneration purges the CMS with nitrogen to release oxygen. Switchover valves alternate the towers, keeping nitrogen flow continuous. High-performance CMS typically runs on 30–60 second cycles. - System Integration & Control (keeps purity on spec)

Stabilize production with a buffer tank and back pressure regulator. Use sensors (O₂, dew point, pressure, flow) and PLC controls to manage cycles, alarms, and shutdowns.

Advantages of Nitrogen Generation by Pressure Swing Adsorption (PSA)

- On-demand production: Nitrogen generation by PSA offers several benefits compared to delivered liquid or bottled nitrogen. Companies can generate nitrogen whenever it needed, without waiting for deliveries or handling high pressure cylinders.

- Flexibility in purity and flow: By using high performance Carbon Molecular Sieve (CMS), purity can adjusted 99.999% to match the application, whether it’s food packaging, laser cutting, or semiconductor manufacturing. This makes PSA suitable for both high volume industries and specialized processes.

- Cost savings: Operating a PSA nitrogen generator typically costs much less than purchasing and transporting nitrogen in bulk.

- Safety and sustainability: Nitrogen generated directly from air, eliminating the risks of storing and handling large cylinders or cryogenic tanks. It reduces the carbon by cutting down on truck deliveries and gas losses.

- Reliability and long service life: Proper pretreatment and maintenance, CMS beds can operate for years, ensuring consistent nitrogen quality and uninterrupted supply for critical operations.

Why the Quality of Carbon Molecular Sieve Matters in Nitrogen Generators?

The quality of Carbon Molecular Sieve (CMS) directly determines the purity, reliability, and efficiency of a PSA nitrogen generator. High grade CMS like CMS450HP, CMS420KT ensures faster oxygen adsorption, consistent nitrogen output, lower dusting, and a longer service life. On the other hand, poor quality leads to frequent re-beds, unstable purity, and higher operating costs.

At SorbiTech™, we supply Carbon Molecular Sieve engineered for strong mechanical strength, fast adsorption kinetics, and minimal attrition. Every batch is tested and packaged under strict quality standards to guarantee consistent performance. By choosing our CMS and combining it with proper loading and maintenance practices, you can achieve stable nitrogen purity, reduced downtime, and maximum return on investment for your PSA system.