Optimize CMS Filling in Nitrogen Generators using Snowstorm Filling

Snowstorm Filling Method

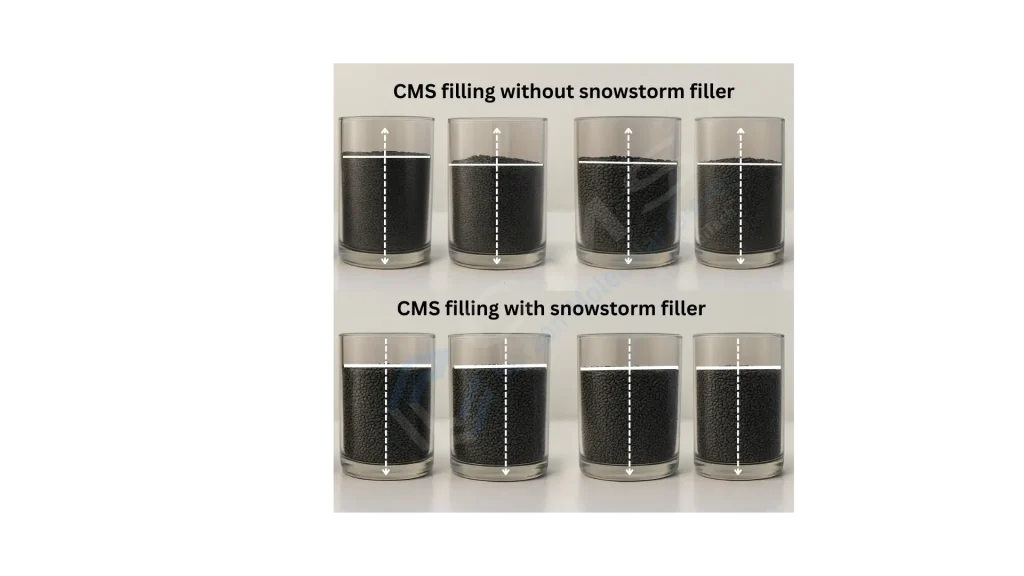

The Snowstorm Filling Method is a specialized process used in PSA nitrogen generators to load Carbon Molecular Sieve into the adsorption columns. Instead of dumping the CMS directly, the material gently poured in under a controlled effect. This ensures the granules settle evenly, creating a uniform and dense packing.

Why the Snowstorm Method Matters?

- Uniform packing and fewer voids: CMS are poured in a controlled, snowfall like manner. This prevents segregation of different particle sizes and avoids gaps or air channels inside the bed. A uniformly packed bed ensures that the air flows evenly through the CMS, improving adsorption efficiency.

- Stable nitrogen purity: When CMS filled loosely or unevenly, it can shift during pressure cycles, leading to channeling and oxygen slip. Snowstorm filling minimizes movement and dusting, keeping the bed stable and ensuring consistent nitrogen purity over long term operation.

- Higher packing density: Compared to simple dumping, this Method achieves a denser bed with more CMS effectively packed into the same volume. A higher packing density improves the separation performance of the PSA system, allowing it to reach the desired nitrogen purity with greater reliability and efficiency.

Common Mistakes to Avoid

- Dump loading: Causes segregation and channels, always use a proper snowstorm loader.

- Raking the top surface: Leads to uneven density. if uneven occur remove and reload instead of leveling manually.

- Loading in humid conditions: Moisture can damage CMS, always load in dry, clean air environments.

How the Snowstorm Filling Method Typically Done?

- Prep the vessel & environment: Make sure the PSA tower is clean, dry, and oil free. Work in a low humidity area so CMS doesn’t absorb moisture before sealing.

- Install bottom supports/screens: Fit bottom screens/retainers/diffusers and check gaskets and seals. Proper seating prevents media loss and bypass during operation.

- Set up the snowstorm loader: Mount a top distribution device (metered hopper with rotor/air assist). Calibrate a steady, low feed rate so CMS falls in a fine, even “snow” across the full diameter.

- Top bed fixation: After reaching the target fill level, install the top screen/retainer and fit Compression Pads (CFL) or spring packs to hold the CMS firmly, limiting movement and dusting during pressure swings.

- Reassemble and verify: Close the vessel, then leak test. On startup with clean, dry feed air, record baseline pressure drop (ΔP vs. flow) and confirm nitrogen purity to verify a stable, uniform bed.

Best Practice for PSA Nitrogen Generators

The most reliable PSA nitrogen systems don’t rely on media alone, they rely on a combination of the right CMS grade and the right filling method. Uneven or poorly packed beds are one of the biggest causes of dusting, purity loss, and shortened CMS life. That’s why leading operators trust the Snowstorm Filling Method, which delivers dense and uniform packing.

At SorbiTech™, we make this best practice simple by supplying both: Carbon Molecular Sieves for high nitrogen purity, and precision engineered snowstorm fillers for correct bed loading. Together, they ensure your generator runs with consistent performance and longer service life.